Powder Coating Tests – Powder Coating Adhesion Test

Powder Coating Adhesion

Test Standard: ASTM D4541-17

The resistance of a coating against pulling off and separating from the surface, which was applied on it, is called adhesion. The adhesion of the powder coating to the substrate depends on many factors including the coating type, the substrate material, substrate conditioning, etc. This complicated phenomenon could be evaluated by different methods which some of them are:

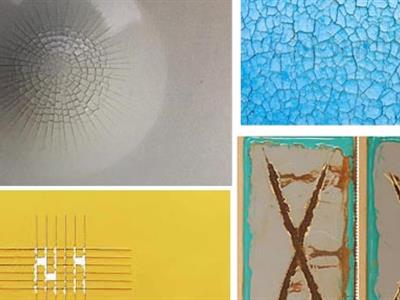

Powder Coating Adhesion Test by Crosshatch Cutting Method

In this method, the cross hatches are created on the cured film, using a tool that has blades with regular intervals, then the adhesion of the powder coating to the surface is determined using a particular tape. This adhesion is divided into 5 levels in the most international standards that according to the ASTM standard, the best situation that creates no separation is reported as B5 and worst situation is reported as B1.

Powder Coating Adhesion Test by Pull off Method

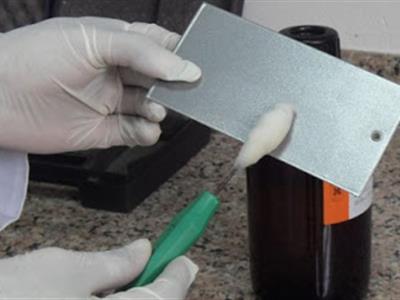

In Pull off adhesion method, some dallies are glued to the coating surface using a particular epoxy tape and after fully curing of the epoxy tape, the required force for separating dolly from coating is reported as the coating adhesion.

Note:

The adhesion of the powder coating to the surface highly affect on the durability properties and is one the most important issues, which should be assessed before and after doing the durability tests. The powder performance against corrosion factors is estimated by the evaluation of the powder adhesion. So, it is one of the first issues of powder properties, which should be considered in the powder formulation and the powder quality.

As it is shown in the figure, the glued dolly on the surface is pulled off using the device, and the pressure amount (Mpa) is indicated. The separation of the dolly could be done from the powder surface (between the glue and the powder), from the substrate surface (the powder with the substrate) or accompanied by separating the substrate (in some cases, the resistance of the concrete surfaces is lower than the powder adhesion).

The factors that lead to reducing the adhesion of the powder coating to the surface

- The inappropriate preparation of the substrate

Considering that, the powder coating is applied on the metallic substrates, so the preparation of the substrate is very important. The lipids (or oil), rusty, dust, etc. on the substrate surface cause a poor adhesion of the coating film to the substrate and finally lead to the adhesion reduction.

- The incomplete curing of the coating

According to the technical properties of each coating, the curing will be completed at a particular temperature and time, nonconformity of the curing conditions causes the incomplete curing and result in the poor adhesion.

- The high thickness of the coating

The coating thickness higher than a defined standard or a compromise between manufacturer and customer is one of the factors for reducing the mechanical properties of the coating.

- Inappropriate formulation

The contradiction of the powder coating with curing conditions and the consumer standards lead to reducing the mechanical properties of the coating.