Powder coating defects and solutions - problems in decorative coatings and wood effects

Some problems occur in decorative coatings that we have listed below. Apart from other problems that we face in decorative coatings, the following problems are specific to these coatings.

Powder coating defects and solutions

Decorative coating and wood effect defects

-

A change in the effects of decorative coatings

Powder coatings with decorative effects include leather, hammer tone, sand texture, crocodile skin, wrinkle and multi-colored. Their effect might change due to various reasons.

- Combining differently structured coatings

- Coating being too thin

- Coating being too thick

- Inappropriate curing temperature

- Improper combining of virgin and reclaim powder

If the ration of virgin to reclaim powder is inappropriate, the decorative effect will have a varied finish. Usually increasing the amount of reclaim powder results in the pattern being tinier, and it lightens the metal color in hammer tone effects.

- Inappropriate distribution of powder particle size

-

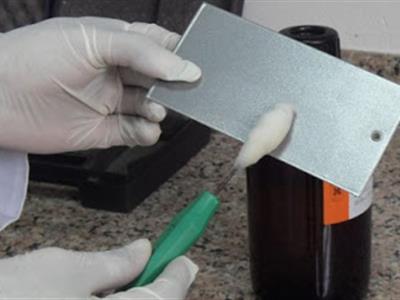

Changes in wood effect coatings

Wood effect is reached through sublimation printing of wood effect on wood effect powder coating. Problems occurring in these types of coatings can be traced to the following:

- Coating being too thin

- Coating being too thick

- Low curing temperature

Should the curing temperature be lower than the standard level, incomplete curing occurs and it increases the likelihood of film or paper sticking to the substrate, on the other hand, curing at low temperature can give the finish a greener tone.

- High curing temperature

- Temperature in the printing process being high

- Temperature in the printing process being low

- Long printing duration

- Low printing duration

Prepared by: Mojtaba Zeinal